How to Build Data Centers Construction Faster Than Ever While Cutting Costs and Boosting Quality

Introduction

Time is money, especially in data center construction. In hyperscale projects, where facilities for tech giants like Amazon, Google, Meta, and Microsoft are delivered under intense deadlines, a single day’s delay can mean millions in lost revenue.

Data centers are not like typical commercial buildings. They require high floor-to-floor heights for large-scale cabling and cooling, heavy-duty slabs capable of supporting massive IT loads, and seamless integration of MEP (mechanical, electrical, and plumbing) systems. An example of a completed and operational data center with professional infrastructure ready for hosting and cloud services.

In such projects, speed and precision aren’t optional, they’re essential to success. To make these ambitious timelines achievable, both reinforcement and formwork must be planned down to the smallest detail. High-quality, well-coordinated shop drawings allow contractors to install each element right the first time, avoiding on-site improvisation and delays.

Why speed is a critical factor in data center construction

Global demand for data centers is accelerating due to growth in AI, cloud storage, and streaming services. Clients expect their facilities to go live quickly, and construction delays directly impact business operations and revenue streams.

This demand pushes construction teams to seek solutions that compress schedules without sacrificing safety or quality.

In many cases, the structural phase is the foundation for all downstream activities. If rebar or formwork drawings contain inaccuracies, the ripple effect can impact the entire project schedule.

The role of planning and BIM integration

In data center construction, precision in planning is as important as the execution itself.

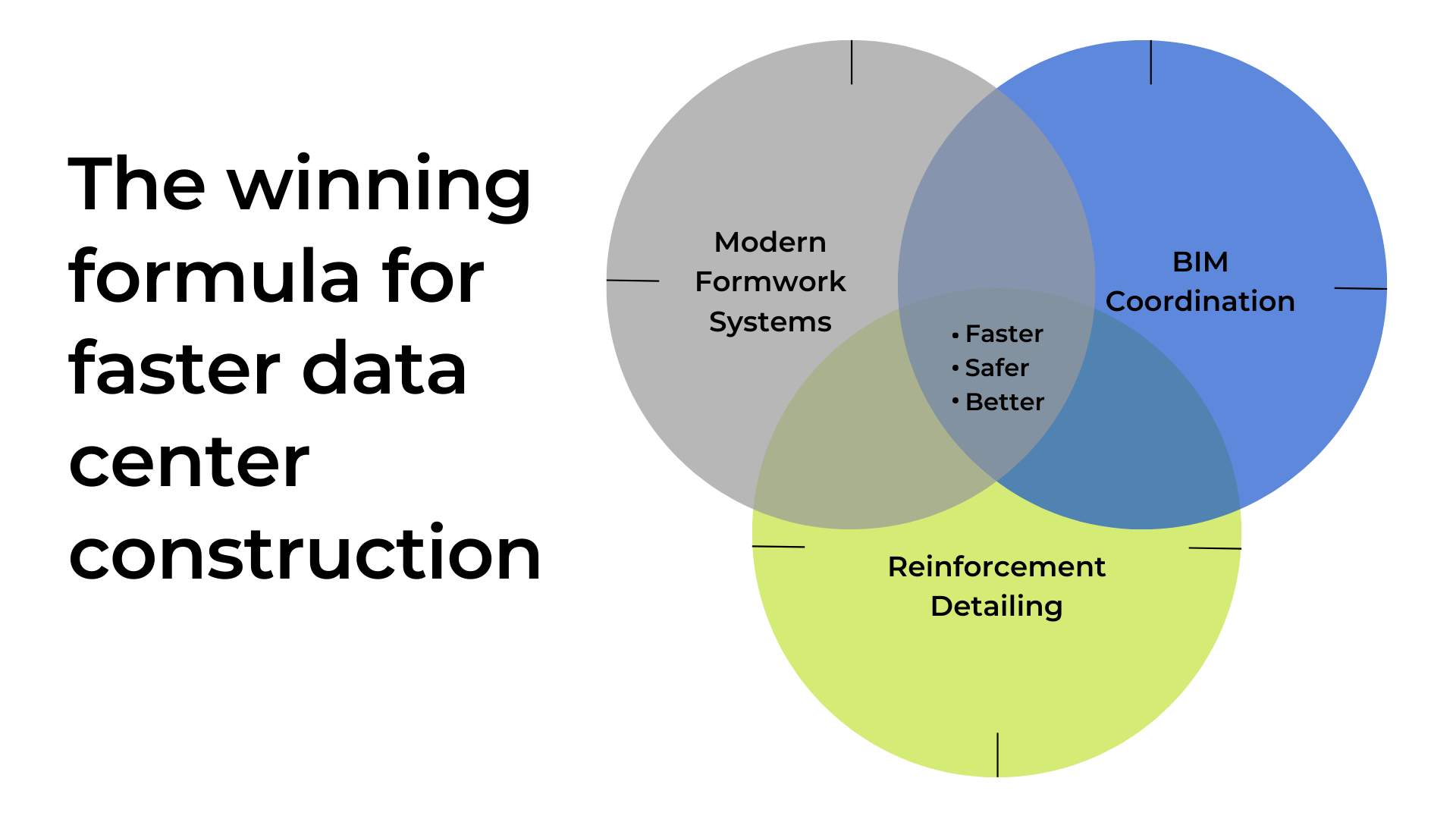

BIM (Building Information Modeling) enables all stakeholders, from structural engineers to formwork suppliers, to work from a shared, clash-free 3D model. This coordination ensures that reinforcement layouts, embedded items, and formwork configurations align perfectly before the first piece of steel or panel arrives on-site. A visual breakdown of the essential components that form the winning formula for building a high-performance data center.

By simulating the construction sequence in BIM, teams can anticipate logistical challenges, optimize crane usage, and coordinate multiple trades to work in parallel without interfering with each other.

Accurate digital shop drawings generated from the model also reduce rework, eliminate ambiguity for site crews, and allow prefabricated components to fit seamlessly into place. The result is a streamlined build process that saves time, reduces cost, and minimizes risk.

Our experience delivering data center projects

Our portfolio at NS Drafter spans multiple hyperscale data center projects across Europe and the United States. Projects defined by aggressive schedules and tight tolerances. On these sites, we’ve seen firsthand how the integration of reinforcement detailing, BIM coordination, and modern formwork systems can dramatically cut structural timelines.

By working closely with contractors and formwork suppliers from the very start, we resolved potential clashes before they ever reached the field. This meant that every pour sequence proceeded without unplanned interruptions, a discipline that has become a standard part of our project delivery approach, allowing us to replicate success across different geographies and scales.

Recently, we spoke with Veljko, one of our project managers who has led several of these builds:

“When deadlines are this tight, there’s no room for improvisation. Every delay in drawings could stop the site.”

Even when design revisions came in late, our team consistently returned corrected shop drawings within 24 hours. Many times, comments would arrive around 8:00 PM our time, with a six-hour time difference, we could make corrections the next morning and still deliver before the client’s crews started work.

The complexity of these builds was equally demanding:

We reinforced a single foundation plan consisting of 15-20 separate pours, each weighing between 660,000 and 1,100,000 lbs (over 1,100,000 lbs per concrete pour).

One plan contained more than 300 unique rebar positions.

We successfully joined a massive monolithic slab with a prefabricated slab so the two would connect seamlessly in both reinforcement and geometry.

We worked in Allplan, Revit, and Navisworks simultaneously for cross-platform coordination.

We delivered a project on time even when the schedule was cut from 12 weeks down to just 4 weeks.

When schedules demanded it, we worked overtime, making sure we were never the weak link in the chain. Beyond speed, we brought efficiency: standardizing bar lengths (40′, 30′, 20′, 10′) and using standard couplers allowed the fabricator to prepare stock in advance, cutting production time and accelerating deliveries to site.

“We weren’t just drawing, we were thinking about how to make life easier for the fabricator and the site team,” Veljko explains.

The most critical period came in late autumn, when year-end targets required a major push. We expanded the team, trained new members, and reorganized to meet urgent requests, sometimes assigning several detailers to a single plan to achieve rapid turnaround.

“They knew that if they sent us something, no matter how urgent, it would come back fast, accurate, and ready to build,” says Veljko.

From start to finish, our role was not simply to produce drawings, but to keep the entire construction engine running at full speed. We combined technical accuracy, logistical awareness, and relentless responsiveness to ensure that not a single day was lost.

For clients, this means one thing: when the stakes are high, the timelines are tight, and precision is non-negotiable, NS Drafter delivers. Not just on paper, but on site, where it matters most.

Traditional formwork limitations

Everything we achieve through precise rebar detailing can be limited if the site execution in reinforced concrete construction doesn’t meet the same level of efficiency.

This is where one of the most persistent structural challenges arises, traditional formwork systems.

Conventional timber or stick-built formwork methods often become bottlenecks. They involve slow, labor-intensive assembly that increases man-hours, a lack of repeatability across complex layouts, and, when combined with the pouring process, result in a significantly less time-efficient overall schedule, especially with the thick floor slabs common in data centers.

These factors extend the structural cycle, delaying other trades like MEP installation and critical equipment placement.

Even with the most skilled crews, traditional formwork struggles when site teams need to constantly adjust due to unclear or conflicting shop drawings. A mismatch between design intent and execution can easily cost days on the schedule.

Advantages of modern formwork systems

Next-generation formwork, whether modular, climbing, or self-climbing, offers substantial advantages. These include faster assembly and removal with reusable, precision-fit panels, greater surface coverage per cycle which reduces the number of lifts, integrated safety platforms for secure work at height, and CNC-cut components delivering tight tolerances with minimal rework.

These systems are engineered to meet both productivity and safety KPIs, aligning with high-value project requirements.

When rebar and formwork shop drawings are fully aligned with the formwork system’s configuration, installation becomes a predictable and streamlined process. Every bar, panel, and insert is placed with confidence, reducing site coordination issues and accelerating progress.

Safety, quality, and labor efficiency gains

In high-stakes projects like data centers, safety cannot be compromised for the sake of speed.

Modern formwork systems integrate guardrails, enclosed platforms, and anti-fall mechanisms that protect workers at height while allowing continuous operations even in adverse weather. These safety measures reduce downtime from incidents and boost crew morale.

Quality is another critical factor. Precision-engineered panels and climbing mechanisms ensure accurate concrete dimensions and surface finishes, minimizing the need for costly and time-consuming repairs.

At the same time, labor efficiency improves because modular formwork reduces repetitive manual adjustments, enabling crews to focus on installation rather than troubleshooting.

The result: faster progress, fewer errors, and safer working conditions without inflating labor costs.

Timeline impact: measurable results

Contractors using modern formwork frequently achieve cycle time per level cut in half, for example from 14 days down to 7 days.

Labor efficiency per crew increases, and parallel workflows such as prefabrication and formwork turnover can run simultaneously.

The result is faster structural completion, enabling earlier commissioning and revenue generation.

In practice, the combination of modern formwork technology and accurate reinforcement drawings multiplies these gains.

It’s not just about faster assembly, it’s about eliminating the stoppages that occur when field crews need to resolve drawing inconsistencies.

Real-world application

On large-scale construction projects, PERI RCS Rail Climbing System has proven to be a fast, safe, and adaptable solution for working at height.

The rail-guided system can be operated with a crane or in a crane-independent hydraulic mode, providing enclosed working platforms that protect crews from wind and weather while ensuring a secure environment for formwork operations.

The modular design allows the same system to be used for different applications from core walls to façade protection and its guided climbing mechanism ensures precise repositioning on each cycle.

According to PERI’s technical documentation, the RCS system is designed to maintain structural alignment and minimize deviations, supporting consistent quality across repetitive lifts.

For projects such as data centers, where precision and cycle time are critical, integrating accurate rebar and formwork drawings with a system like RCS means contractors can maintain steady progress and reduce the risk of delays caused by on-site adjustments.

Conclusion

Modern formwork systems are more than temporary molds, they’re essential tools for meeting the speed, precision, and quality demands of hyperscale data center projects.

When combined with BIM-driven, clash-free reinforcement and formwork drawings, they enable faster cycles, safer operations, and consistent accuracy.

The real advantage comes from integrating technology with thorough planning and early coordination.

This approach minimizes rework, keeps schedules on track, and delivers projects ready for handover ahead of deadlines, a decisive edge in today’s competitive data center market.