10 Powerful Insights from the Field for Shop Drawing and Rebar Detailing

Introduction

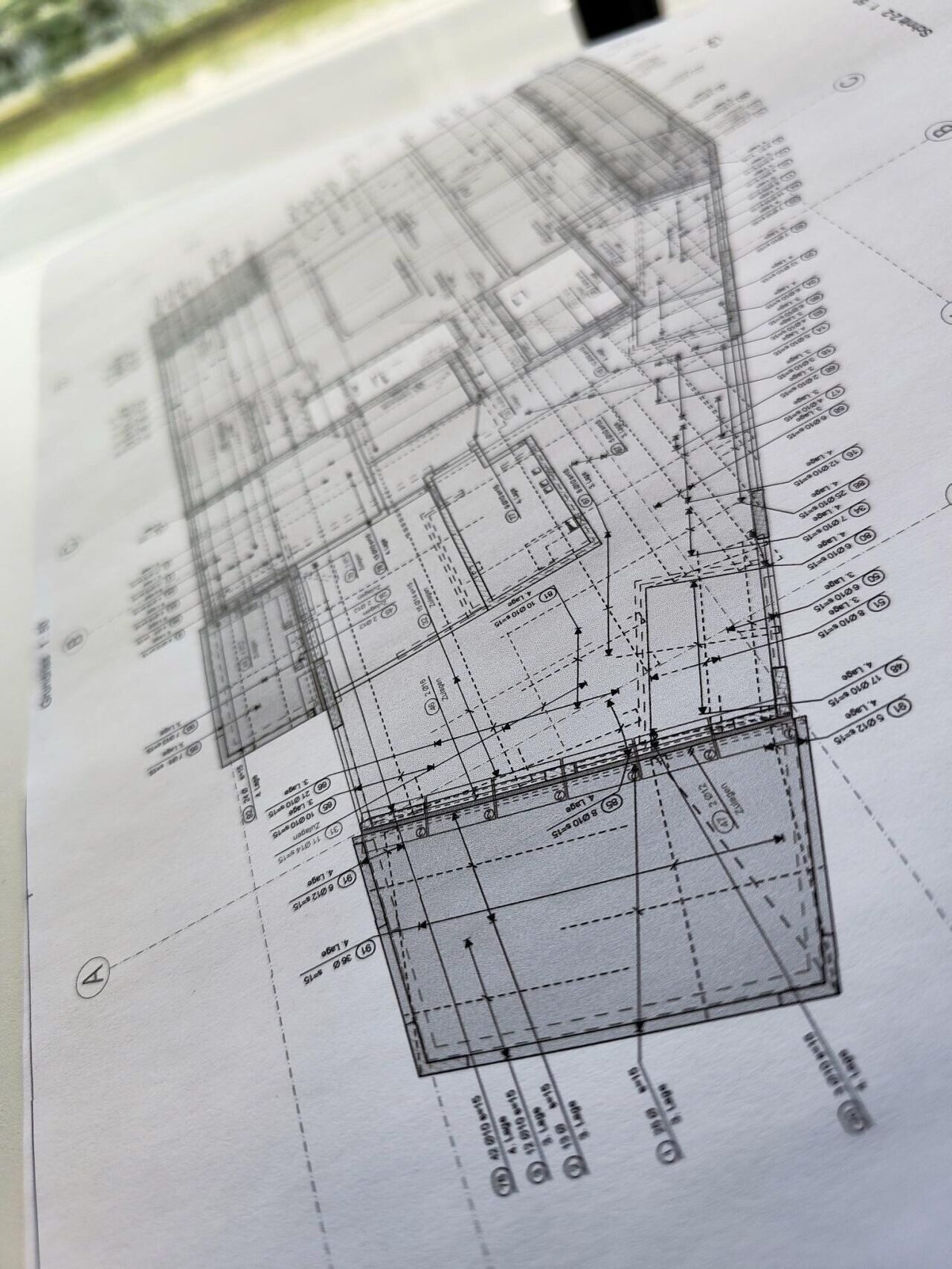

In today’s construction industry, digitalization is the norm. From BIM models to clash detection and advanced rebar modeling software, most rebar detailing now happens on-screen using platforms like Allplan and Autodesk Revit. These tools deliver precise 3D models, accurate quantity takeoffs, and coordinated designs.

However, one critical element often gets overlooked, the field experience of the team creating the shop drawings. No matter how perfect the model looks in software, rebar is installed on real job sites, not in computers. If a shop drawing can’t be interpreted or executed by site crews, the design fails its purpose.

That’s why real-world insight must complement digital skill. Only someone who’s stood next to formwork, observed tight-space installations, and spoken with on-site workers understands what makes rebar detailing truly constructible. Because in the end, the best shop drawings aren’t just correct, they’re buildable.

From screen to site

You may have come across shop drawings that look perfect in a 3D model, but fail during real-world execution. These issues often stem from a lack of practical, on-site understanding. Consider these common challenges:

Unbuildable details

Just because something fits in the model doesn’t mean it can be built. Tight rebar spacing, unrealistic bend radii, or congested reinforcement in complex joints may pass clash detection but become nearly impossible for workers to tie and install. These “unbuildable” details slow down progress and often force site crews to improvise.

Incorrect lap lengths

Lap splices that are too short may fail to meet structural or code requirements, while those that are too long lead to material waste and complications during staged pours. Proper laps should consider not just code, but construction phasing, accessibility, and sequencing.

Unrealistic connection zones

Connection zones such as beam-to-column joints, wall intersections, or slab edges are often more complex in reality than they appear in the model. A joint that looks simple in 3D may, in fact, require partial removal of formwork, custom cutting of bars, or rework due to missed clearances. Without visiting the site or discussing these zones with field teams, detailers may underestimate the effort needed to make these areas work.

Overloaded drawings

Shop drawings filled with technical data, annotations, and symbols may appear “complete” to the drafter, but can be overwhelming or unclear for field crews. A drawing packed with information but lacking clear build logic is often counterproductive. Workers need to see what goes where, when, and how not just a wall of tags and bar marks. Prioritizing clarity and sequencing over information density makes all the difference in execution.

Why field experience sets our detailing apart?

Our team doesn’t just sit behind screens. We regularly visit construction sites, collaborate with contractors, observe installations, and incorporate those lessons into every shop drawing we produce. You can see our work here.

A great example is a recent site visit by our colleagues Aleksandra Glendza, Mladen Morača, and Nikola Gojkov. During this visit, we observed firsthand how our shop drawings are used on an active construction site. We also sat down with Nikola Gojkov, who was on-site, to capture his insights from the field. His perspective clearly shows how rebar detailing changes when drafters see their work come to life under real-world conditions.

Read the full interview with our colleague Nikola Gojkov below and discover how one site visit can shift the mindset of any rebar detailer.

Q: What was the main reason for your visit to this particular construction site?

The visit was initiated because our clients were pleased with the speed and quality of our shop drawings and wanted to meet us in person. Over three days, we toured their offices, met the people we collaborate with daily, and visited the construction site where our rebar detailing is being implemented. Seeing our work become physical reality was a valuable experience, one that connects digital modeling with real-world construction.

Q: What were your first impressions on-site compared to the 3D model?

The scale of the project struck me immediately. While everything seems clean and manageable in the model, being on-site reveals the full dimensions: bar lengths, reinforcement density, and spatial constraints. It shifts your perspective. You begin to think not just about modeling, but about logistics, manpower, and the physical challenges of installation.

Q: What was the most useful thing you heard directly from the contractors during conversations?

One of the most useful things came from the introductory presentation they gave us upon arrival. They explained the project we had worked on in detail, including the reasons why it was designed and executed in a particular way. Especially valuable were the site-specific constraints and conditions, which helped us understand the bigger picture, both technically and logistically.

Q: Did you see how our shop drawings are used on-site? Were they clear to the workers at first glance?

Yes, I saw our shop drawings being used directly on-site, and it was a very useful experience. Most workers understood the shop drawings well, especially when they were clearly organized, with logical tags and clean visuals. This experience reminded me how important it is that drawings aren’t just technically correct, but also intuitive and usable by the people on the ground.

Q: Did you encounter a situation where contractors pointed out that a solution we modeled/drew made installation easier?

Yes, in one element zone it turned out to be more practical to use a greater number of smaller diameter bars instead of fewer large-diameter ones. Although this may seem less efficient in terms of material, contractors confirmed that it was much easier to install, in terms of handling and precision placement in confined space.

Q: How did this experience help you think differently about details like laps and connection zones?

This experience gave me the whole new outlook. Now when I draw, I don’t just think “is it according to code,” but also “is it feasible,” “can the workers install it without complications,” and “will the joint actually work in given conditions.” This insight directly impacts the quality of the solutions we offer, not just as drawings, but as applicable and efficient solutions on-site.

Q: In your opinion, how much does the clarity and precision of our shop drawings speed up execution and ease work on-site?

We aim for every drawing to be clear, compliant with standards, and easy for contractors to read. Even in 2D projects, we use different layers to highlight key information and assist with installation. A good shop drawing leaves no room for doubt, and that’s what saves time and prevents execution errors.

Q: Is there a moment from the site that really stayed with you as a lesson or confirmation that we’re doing the right thing?

When people who until then knew you only through emails and drawings invite you to visit, take time to walk you through the project, and even beyond that, to show you the city, take you to dinner, tell you stories that don’t appear in the specs… You know you’ve made an impact.

These aren’t just social gestures, but signs that we’ve earned their trust. That our work wasn’t just “another file in the inbox,” but a real contribution to something that’s being built and will remain. And that’s maybe the best feeling this job can give.

Q: Would you recommend that every team member visits a site at least once? Why?

Definitely. Nothing replaces the moment you see your own drawings brought to life. You realize your work has real value, and that gives you extra motivation for the next project.

Q: Why is it important that the team clients hire has experience and understanding of real site conditions, and not just rely on digital models?

Models and drawings are essential tools, but the real value only comes when the team knows how to apply them in real conditions, with all the technical, logistical, and time-related challenges that the field brings. Working in real conditions teaches you to design solutions that can actually be executed, to consider space limitations, installation sequences, equipment availability, and coordination with other contractors.

That’s why I always recommend not to look just for software expertise, but for practical experience. A team that understands how reality works gives you the confidence that things will not only be drawn, but actually built.

Shop drawings are more than just paperwork

We don’t create drawings just to meet documentation requirements. Our shop drawings are practical tools-designed to guide contractors step by step through the rebar installation process.

They include clear, organized, and actionable information: dimensions, bar marks, placement sequences, and material specifications designed to facilitate accurate execution on site.

These drawings aim to bridge the gap between design and construction. By providing a visual and technical reference on-site, they help improve coordination, reduce miscommunication, and support more efficient decision-making during installation.

Standing in front of a drawing during construction, it becomes more than just a technical document, it functions as a guide that helps align design intent with what’s actually being built, step by step.

How field experience improves drawing quality?

Practical buildability

Engineers who’ve been on-site know how much space is actually available for rebar installation, how bars are bent and connected, and where errors most often occur. They draw with the understanding that they’re not modeling for a screen, but for people who will install it.

Clash prevention

In a BIM environment, clash detection can miss practical problems like bars that can’t be installed without extra tools. A field-experienced detailer can spot such situations before they happen.

Better communication with contractors

Teamwork is key to success. Detailers who know the field also know how to communicate with rebar workers, site supervisors, and installers. Their drawings are clear, precise, and free of “theoretical” solutions that don’t work in practice.

Faster problem-solving

On-site, time is money. When there’s a discrepancy between drawings and real conditions, a team with field experience can quickly react and offer an immediately applicable solution, without delays or work stoppages.

Conclusion

There’s something special about standing on a construction site and recognizing your own drawing, not on paper, but embedded, connected, poured. You realize you didn’t just “draw a bar.” You drew a workflow. A construction rhythm. That’s why, to us, shop drawings are more than documentation.