Top 10 Most Essential Features in Tekla Structures For Rebar Detailers and Engineers

Introduction

In today’s fast-paced construction industry, efficiency, precision, and collaboration are critical. As we explained in our guide to rebar detailing, even small errors can cause big delays on-site. Projects are becoming increasingly complex, deadlines shorter, and the pressure to deliver accurate and complete models is higher than ever. Engineers and detailers are expected to bridge the gap between digital design and real-world execution without errors. In this context, BIM tools like Tekla Structures have become indispensable in daily workflows. Tekla has been standing out for years as a leading platform for detailing reinforced concrete and steel structures. Whether you’re a structural engineer, rebar detailer, or BIM coordinator, Tekla Structures offers an exceptionally powerful set of tools tailored to your workflow.

Here is an advanced guide to the top 10 most essential features in Tekla Structures that every engineer and rebar detailer should use to improve accuracy, speed, and drawing quality.

Intelligent Rebar Modeling Tools

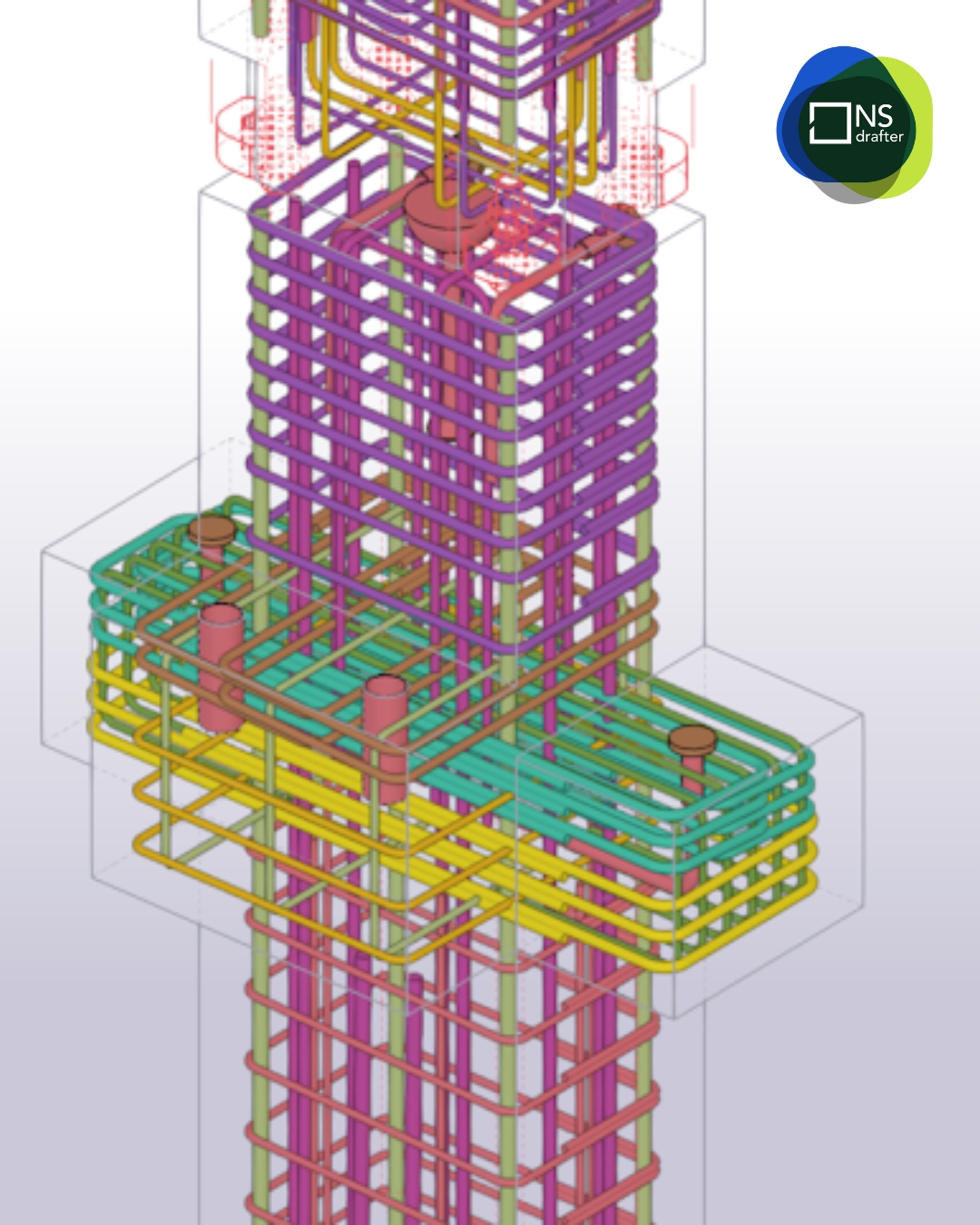

Tekla Structures allows you to model every piece of reinforcement in 3D, including bars, meshes, and complex shapes. You can define lap splices, bar ends, and custom bending shapes with great accuracy. This not only improves visualization but ensures that the reinforcement will fit exactly as planned on-site.

Built-in clash detection ensures constructability from the earliest stages of modeling.

Additionally, layering reinforcement properly (top/bottom) within slabs and walls helps prevent clashes and simplifies field installation. This feature is essential for maintaining control over bar placement in dense reinforcement zones. It greatly reduces the time spent on coordination and site revisions, making it one of the most critical modeling tools in Tekla.

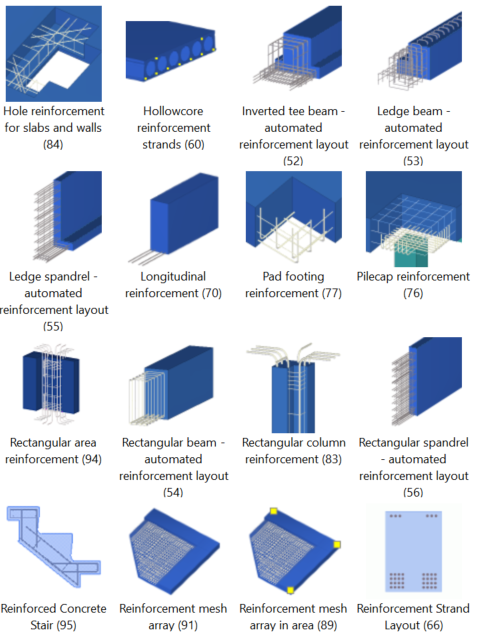

Rebar Sets and Automated Placement Tools

Tekla’s Rebar Sets allow reinforcement to be defined parametrically based on host geometry, automatically adjusting as the concrete model changes. These tools speed up the detailing of walls, slabs, and beams while maintaining full control over bar size, spacing, and cover.

Grasshopper integration enables reinforcement of even the most complex CIP shapes, making this a must-use feature for advanced modeling needs. With these automation tools, detailers can model faster while maintaining high accuracy, especially on large repetitive projects. This is a game-changer when deadlines are tight and quality cannot be compromised.

Cast Unit Management

Grouping reinforcement, embeds, and concrete into Cast Units streamlines fabrication, assembly drawing creation, and quantity takeoffs. Cast Units are essential for prefabrication workflows and help structure teams organize and manage concrete pours more effectively. xDrawer plugin can be used to automate assembly drawing generation, saving time while preserving quality and standards.

This feature ensures that all components are properly grouped, labeled, and tracked across design and production stages. It’s extremely useful in precast environments where standardization and control are key. Cast Unit Management also improves traceability by linking reinforcement and embeds directly to pours, giving project managers and site teams a clear overview of what belongs to each pour sequence. This reduces errors during fabrication and helps coordinate logistics with precast plants or on-site teams.

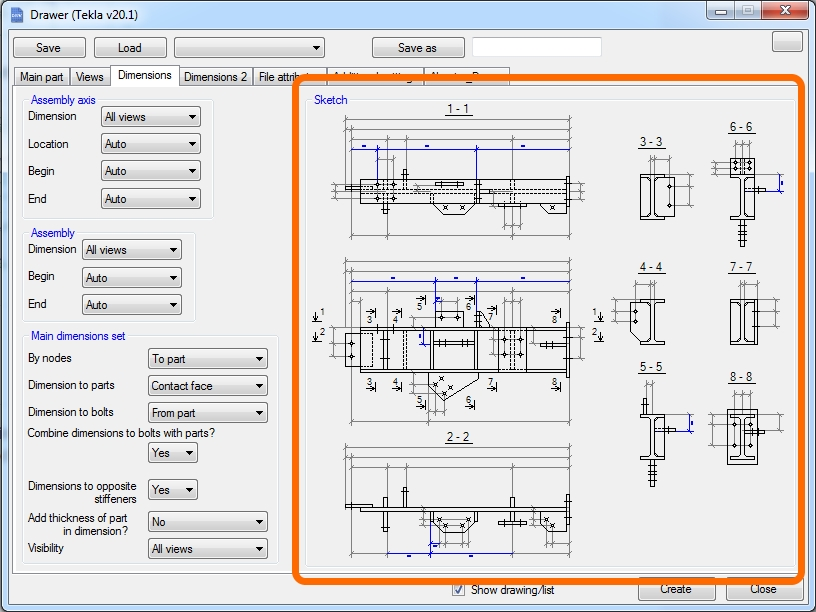

Drawing Templates and Documentation Automation

Tekla’s customizable drawing templates allow you to automatically produce consistent and accurate shop drawings, GA drawings, and bar bending schedules (BBS). This reduces manual drafting, improves standardization, and speeds up approvals. You can also automatically generate formwork drawings and layout plans directly from the model, helping streamline site execution.

The ability to customize templates ensures compliance with national and client-specific standards. This feature is invaluable for teams that manage multiple projects and need to maintain consistent documentation quality. Well-structured templates also speed up revisions, as title blocks, dimensions, and tables update automatically whenever the model changes. This ensures all project stakeholders work with the latest, approved documentation without the need for repetitive manual corrections.

Export to Fabrication and Field Equipment

Export reinforcement directly from Tekla to BVBS format for bending machines, or IFC for coordination with other disciplines.

PDF export ensures traditional workflows remain supported.

Point Layout tools enable the export of layout data to robotic total stations, ensuring precise on-site positioning for both reinforcement and formwork.

These exports reduce manual entry errors and speed up production in the shop and on-site. It’s a must-have for teams looking to improve the link between digital models and real-world execution. By enabling direct digital transfer from the model to machinery, Tekla eliminates duplication of work and minimizes costly human errors.

This not only accelerates fabrication and layout but also provides an auditable link between design and execution.

Template Editor and Reporting Tools

Use the Template Editor to create custom BBS formats, material summaries, and quantity takeoff reports. These reports pull live data from the model, ensuring accuracy and alignment with construction needs.

Assigning UDAs (User-Defined Attributes) like bar diameter, material grade, or concrete strength helps automate and customize these reports for different elements. With accurate reporting, project managers gain better control over costs and materials.

This feature is especially powerful when used in complex or high-volume projects requiring detailed tracking. Custom reports allow companies to align deliverables with both internal standards and client requirements. This flexibility ensures that stakeholders always receive the right level of detail, whether for cost estimation, procurement, or site coordination.

Multi-User Collaboration with Model Sharing

Tekla’s Model Sharing feature allows multiple users to work on the same model simultaneously, regardless of location. This is crucial for large teams or multi-disciplinary coordination.

Combined with Trimble Connect integration, this ensures real-time synchronization between design offices and field crews. Model Sharing minimizes downtime and ensures the latest design information is always available. It’s one of Tekla’s most valuable tools for distributed teams and tight project schedules.

This collaboration method also enhances accountability, since every change is tracked with user and time stamps. Teams benefit from full transparency in design development, which reduces conflicts and streamlines approvals.

Custom Components and Macros

Create parametric custom components for repetitive modeling tasks, such as starter bars or slab edge reinforcements. Macros can further automate repetitive operations, reducing manual work and potential errors. Use Grasshopper for creating custom components in CIP projects with non-standard geometry.

These tools significantly reduce modeling time and improve consistency. In complex projects, this flexibility translates into measurable efficiency gains and reduced detailing errors. Developing a library of reusable custom components helps companies maintain consistency across multiple projects. It also empowers less experienced modelers to produce complex details with confidence, while maintaining company standards.

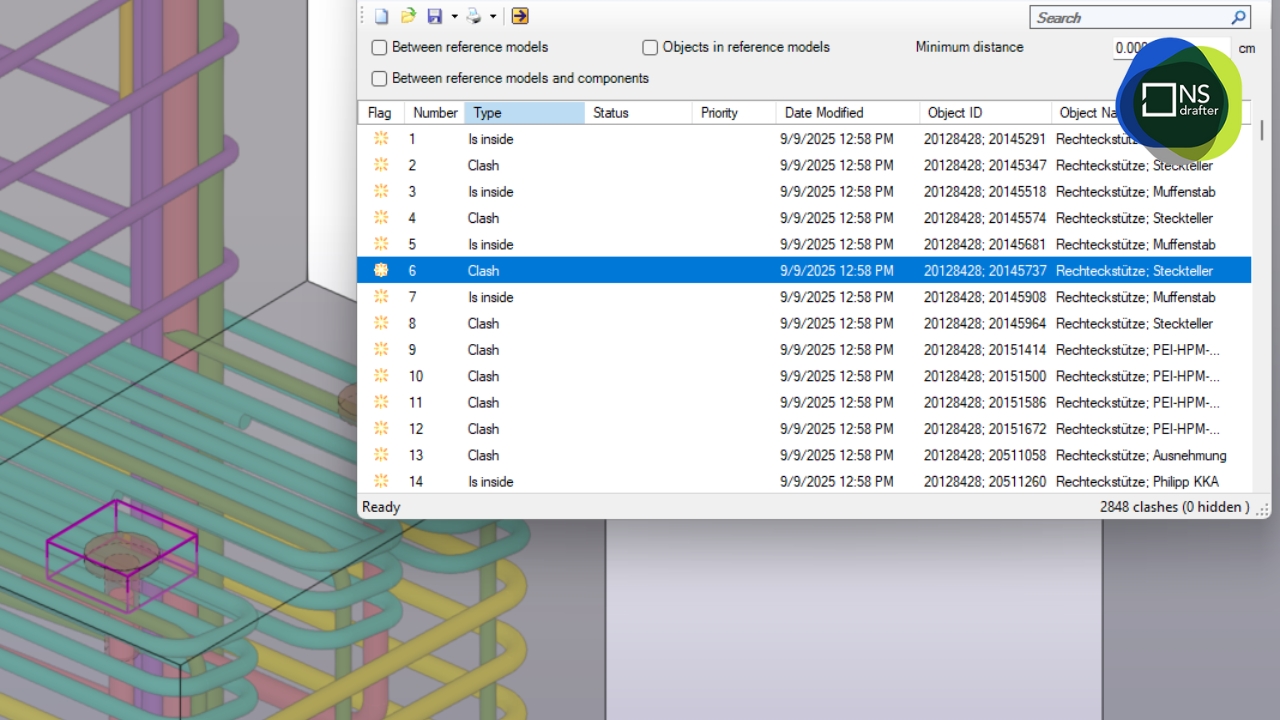

Clash Detection and Coordination with Trimble Connect

Identify potential conflicts between reinforcement, formwork, and embedded items using Tekla’s built-in clash detection tools. For broader coordination, use Trimble Connect to review models with architects, MEP engineers, and site personnel.

This ensures issues are caught early in the design phase, avoiding costly changes during construction. Catching clashes early reduces RFIs and change orders during construction. This feature is essential for any project involving multiple trades or tight tolerances.

Field Layout and Execution Support

Tekla supports the full BIM2Field workflow. With tools for exporting layout points, generating shop drawings, and updating field crews in real-time, it bridges the gap between design and construction.

Real-time coordination through Trimble Connect and use of robotic layout stations ensures accuracy and boosts productivity on-site. This tight feedback loop between office and field minimizes delays and improves build quality.

It’s one of the most practical and impactful features for site execution. By integrating design data directly into field equipment, Tekla enables crews to focus on quality and speed rather than manual interpretation of drawings. This significantly reduces rework and builds confidence in the model-driven process.

Conclusion

Tekla Structures is more than just a modeling platform, it’s a comprehensive solution for end-to-end construction planning, detailing, coordination, and execution. When used to its full capacity, it drastically reduces errors, accelerates project timelines, and improves cross-team collaboration.

These top 10 features not only simplify the modeling and detailing process, but also enhance downstream workflows such as fabrication, logistics, and on-site assembly. Whether you’re detailing complex rebar cages, managing large-scale precast elements, or coordinating field layout with robotic stations, Tekla provides all the necessary tools in one ecosystem.

For companies aiming to stay competitive in the evolving construction landscape, mastering these capabilities is not optional, it’s essential.

FAQ

Q: Is Tekla Structures only suitable for large-scale projects?

A: Not at all. While it excels in complex and large-scale projects, many small and mid-size companies use Tekla successfully for residential, infrastructure, and light industrial work thanks to its scalability and customization.

Q: How steep is the learning curve for Tekla Structures?

A: The learning curve depends on your background. Engineers and detailers familiar with 3D modeling or BIM concepts usually adapt quickly. Tekla also offers extensive tutorials, user guides, and community support.

Q: Can I use Tekla Structures for both cast-in-place and precast detailing?

A: Absolutely. Tekla supports both workflows, including automation tools for CIP modeling (e.g., using Grasshopper) and cast unit management for precast production.

Q: How does Tekla integrate with other software like Revit or AutoCAD?

A: Tekla supports IFC, DWG, DGN, and other formats for model import/export. For live collaboration, Trimble Connect bridges the gap between Tekla and other platforms.

Q: Is Trimble Connect included with Tekla Structures?

A: Yes. Trimble Connect is part of the Tekla ecosystem and is used for cloud-based model sharing, issue tracking, and field coordination.

Q: How does Tekla improve site execution?

A: With layout point exports, real-time data access through Trimble Connect, and clear shop drawings, Tekla enables precision and efficiency on-site, minimizing mistakes and rework.

Q: What’s the biggest benefit of using Tekla Structures?

A: The biggest benefit is integration. Tekla combines modeling, detailing, documentation, collaboration, and execution tools in one environment, drastically improving the quality and efficiency of construction projects.