Successful Construction Case Study: 46,500 m² in Graz

Overview Of The Construction Case Study

Project Location

The project was developed in Graz, Austria, a city known for strict building regulations, high engineering standards, and a strong emphasis on construction quality, as defined by national construction standards in Austria.

Delivering a rebar detailing service in this environment required careful interpretation of structural design documentation and transformation of engineering calculations into clear, buildable reinforcement drawings.

From the earliest project stages, the focus was placed on clarity, consistency, and practical applicability of detailing rebar. This approach supported smooth coordination between design intent and on-site execution.

The building is designed as a reinforced concrete structure with a clear load-bearing hierarchy. Vertical loads are primarily carried by reinforced concrete walls and columns, while floor slabs act as horizontal load-distributing elements, ensuring efficient transfer of loads to the supporting structure and ultimately to the foundation system.

Detailing rebar for such a system requires a strong understanding of load paths, reinforcement continuity, anchorage principles, and construction sequencing.

Reinforcement arrangement were developed to ensure compatibility between structural calculations and practical execution on site.

Scope Of Rebar Detailing Service

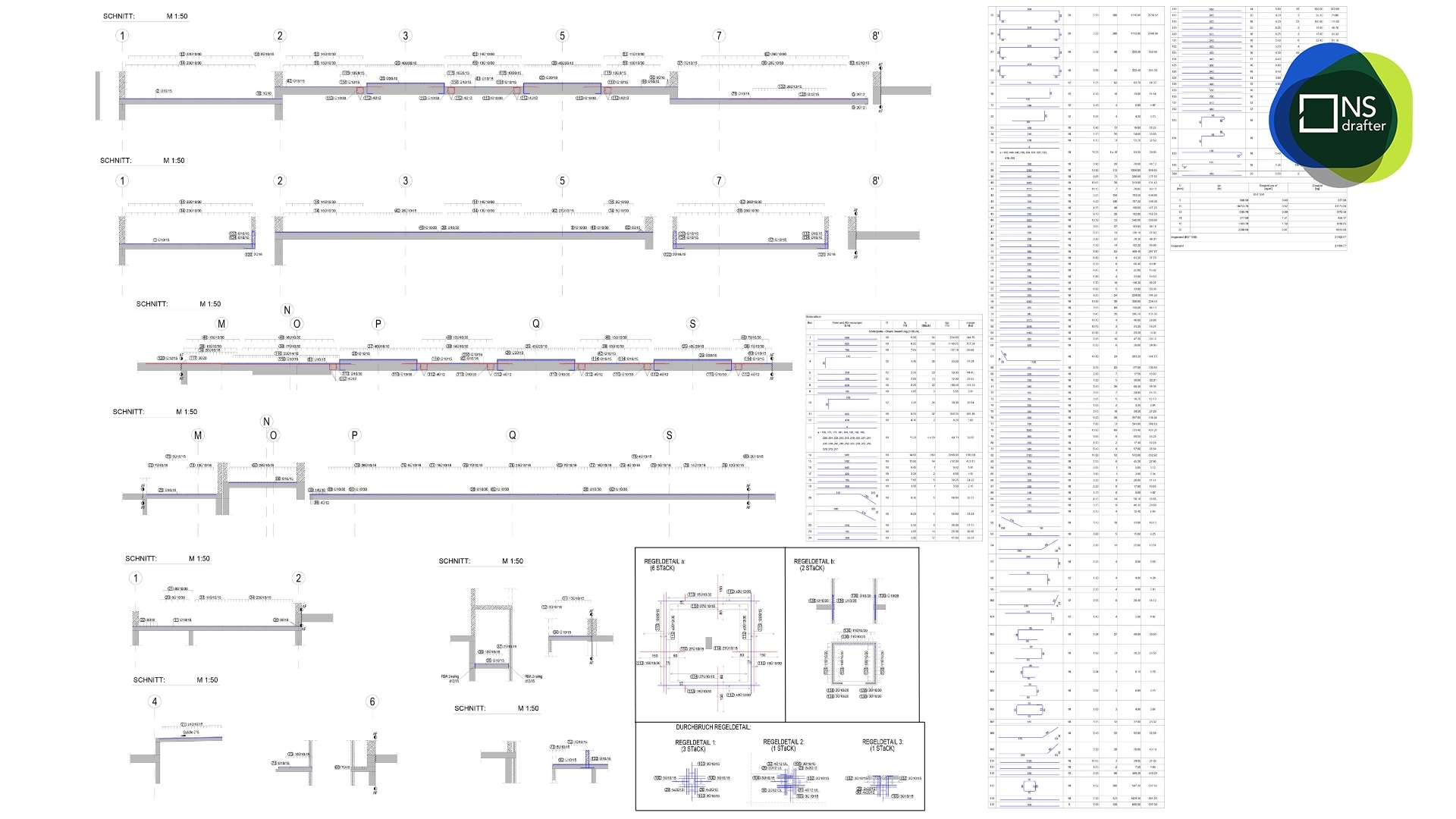

The rebar detailing service provided for this project included complete structural documentation covering both geometry and reinforcement. The project was fully detailed using ArmCad software.

The scope of work included:

reinforcement drawings for slabs, walls, columns, and local beams

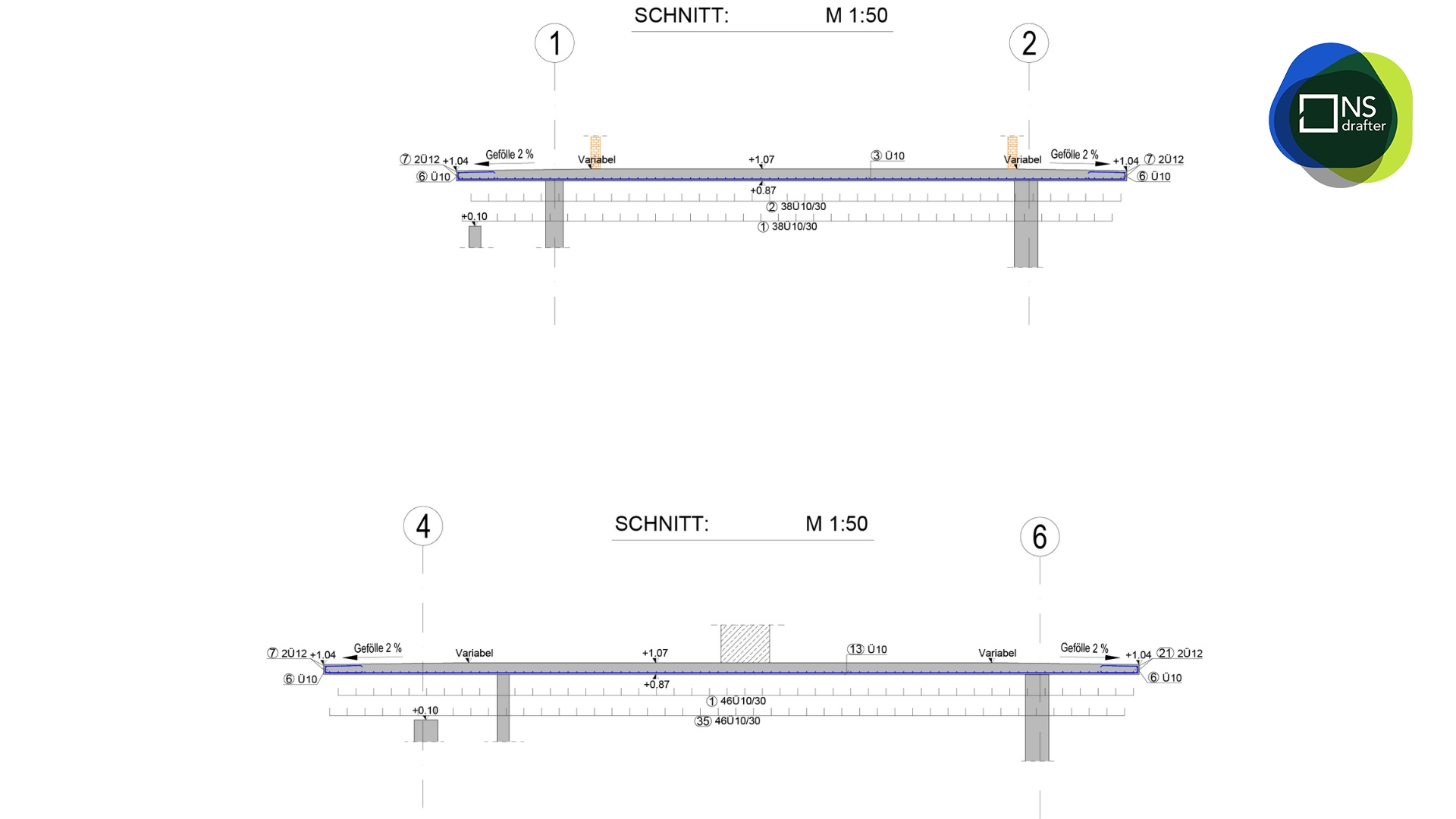

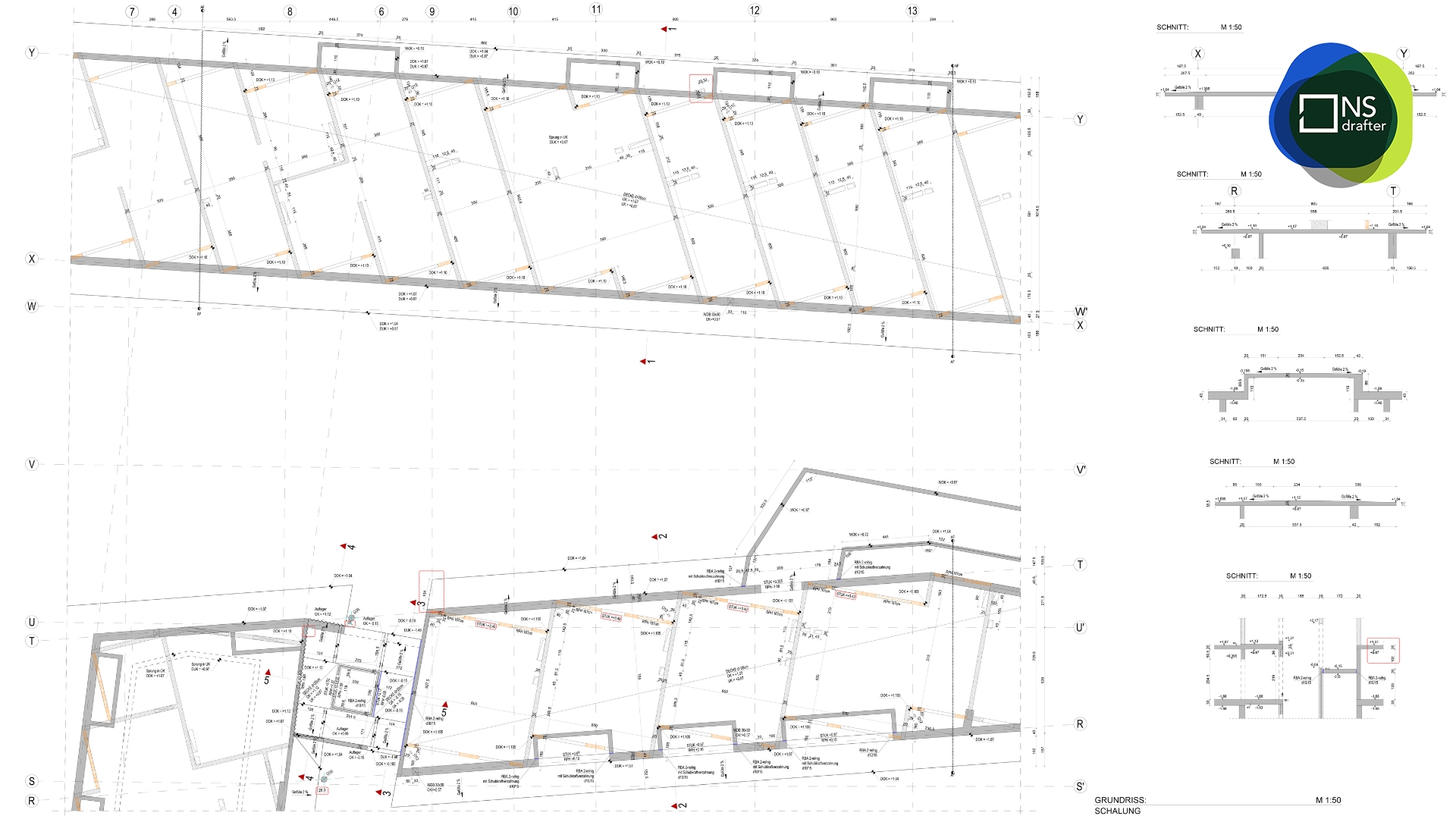

formwork drawings defining concrete geometry and elevation levels

sections and characteristic reinforcement details

All drawings were prepared with site usability in mind, minimizing ambiguity and reducing the need for clarifications during construction.

Basement Levels And Structural Complexity

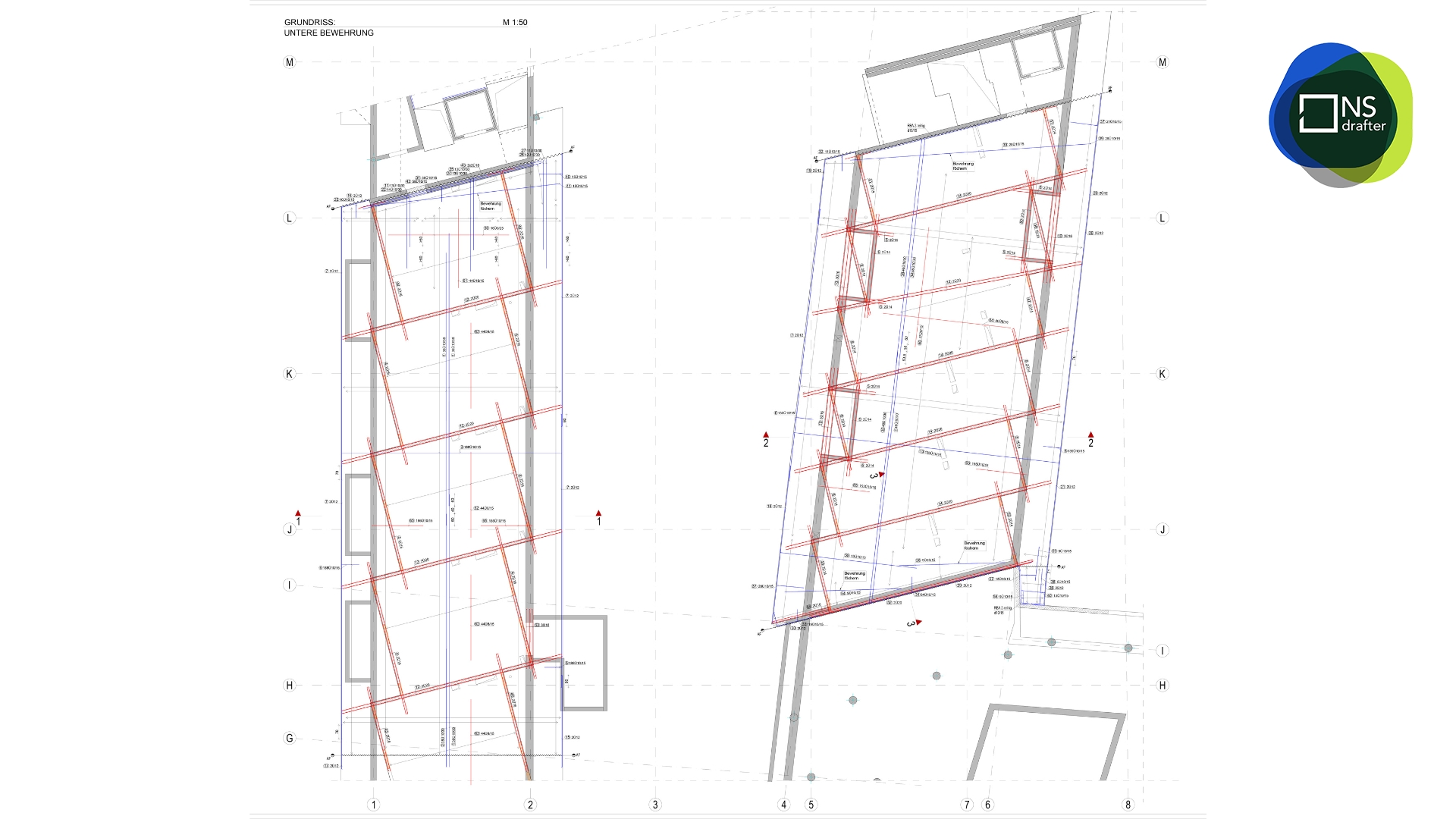

The two underground levels were the most technically demanding part of the project. These levels include parking garages and technical spaces with large spans, increased loads, and demanding environmental conditions.

Basement structures are exposed to lateral soil pressure and moisture, which significantly increases the importance of accurate detailing rebar. The scope for the basement levels included detailed foundation slab reinforcement layouts, vertical and horizontal reinforcement for retaining walls, and additional reinforcement around ramps, openings, and service penetrations.

Special attention was given to reinforcement continuity between slabs and walls, as this directly affects crack control, watertightness, and long-term durability of underground structures. In projects of this type, such continuity is not only a structural requirement but a key performance factor, especially in basement levels exposed to permanent soil pressure and moisture.

Any discontinuity or improper anchorage at these interfaces can lead to water ingress, reduced service life, or costly remediation work.

Ground Floor As A Structural Transition Zone

The ground floor represents a critical transition between the basement structure and the superstructure above. Structural layouts often change at this level due to architectural requirements, which demands careful coordination in detailing rebar.

For the ground floor, our company focused on accurate slab reinforcement layouts, column-to-slab connection details, and continuation of shear walls from basement levels.

Precision at this level is essential because detailing errors can propagate into multiple floors above.

Upper Floors And Repetitive Structural Levels

Above the ground floor, the building includes seven upper floors. These floors follow a similar structural concept but include local variations driven by architectural and functional requirements.

Our company, for the upper floors emphasized consistency and standardization where possible, while still addressing floor-specific conditions.

Our company, for the upper floors emphasized consistency and standardization where possible, while still addressing floor-specific conditions.

Detailing rebar included bottom and top slab reinforcement, column anchorage and lap splice detailing, and reinforcement continuity between floors. Core walls for staircases and elevators were detailed with consistent reinforcement layouts to ensure vertical load transfer and lateral stability.

Formwork Drawings And Their Role In The Project

Formwork drawings were a fundamental part of the project and a critical component of the rebar detailing. They provided the geometric basis for all reinforcement drawings and ensured alignment between structural and architectural layouts.

The formwork documentation defined:

exact slab, wall, and column dimensions

concrete thicknesses and elevation levels

construction joints and openings

Accurate formwork drawings significantly reduced the risk of conflicts and on-site adjustments during construction.

Rebar Quantities And Material Optimization

Accurate quantity control was one of the main objectives of the rebar detailing service on this project. Precise detailing rebar allowed reliable reinforcement quantity take-offs, supporting procurement planning and reducing material waste.

For a project of this scale, accurate quantities are essential for cost control and predictable construction scheduling. High-quality rebar detailing directly contributes to economic efficiency.

The large volume of drawings and frequent design updates required a structured approach to coordination and quality control.

Key quality measures included:

consistent drawing standards

logical bar marking systems

internal technical reviews

This disciplined approach ensured stable documentation quality throughout all project phases.

Value Of Professional Rebar Detailing Service

This project clearly demonstrates the value of professional rebar detailing service for large reinforced concrete buildings. Accurate detailing rebar improves construction accuracy, reduces rework, and supports predictable project execution.

In environments with high construction standards, such as Austria, professional rebar detailing is essential.

Conclusion

This project in Graz, Austria demonstrates how experienced detailing rebar supports structural safety, construction efficiency, and cost control on large-scale reinforced concrete buildings. High-quality rebar detailing service is a fundamental requirement for long-term performance and successful execution.

For those looking for similar case study examples in the field of reinforced concrete construction, this project offers valuable insights into best practices, coordination strategies, and quality standards.

FAQ

- What is a rebar detailing?

A rebar detailing is the process of creating detailed reinforcement drawings that define the exact placement, size, spacing, and configuration of reinforcing steel used in concrete structures. - What problems does rebar detailing solve in construction projects?

Rebar detailing prevents reinforcement clashes, reduces construction errors, improves material efficiency, and ensures that structural designs can be built correctly on site. - What deliverables are included in a rebar detailing service?

Typical deliverables include reinforcement drawings for slabs, walls, columns, and beams, formwork drawings, sections, and detailed reinforcement layouts for critical structural zones. - How does rebar detailing differ from structural engineering design?

Structural design defines required reinforcement based on calculations and codes, while rebar detailing focuses on arranging that reinforcement into clear, buildable drawings for construction teams. - Can rebar detailing reduce construction costs?

Yes. Accurate rebar detailing improves quantity accuracy, reduces steel waste, minimizes rework, and supports efficient construction planning. - When should rebar detailing start in a project?

Rebar detailing should start as soon as structural design is sufficiently developed, ideally before construction begins, to avoid delays and on-site modifications.