5 Powerful Benefits of BIM Clash Detection for Your Construction Project

Introduction

With the increasing complexity of construction projects and growing demands for precision, the use of Building Information Modeling (BIM) technology has become essential for minimizing errors and optimizing workflows.

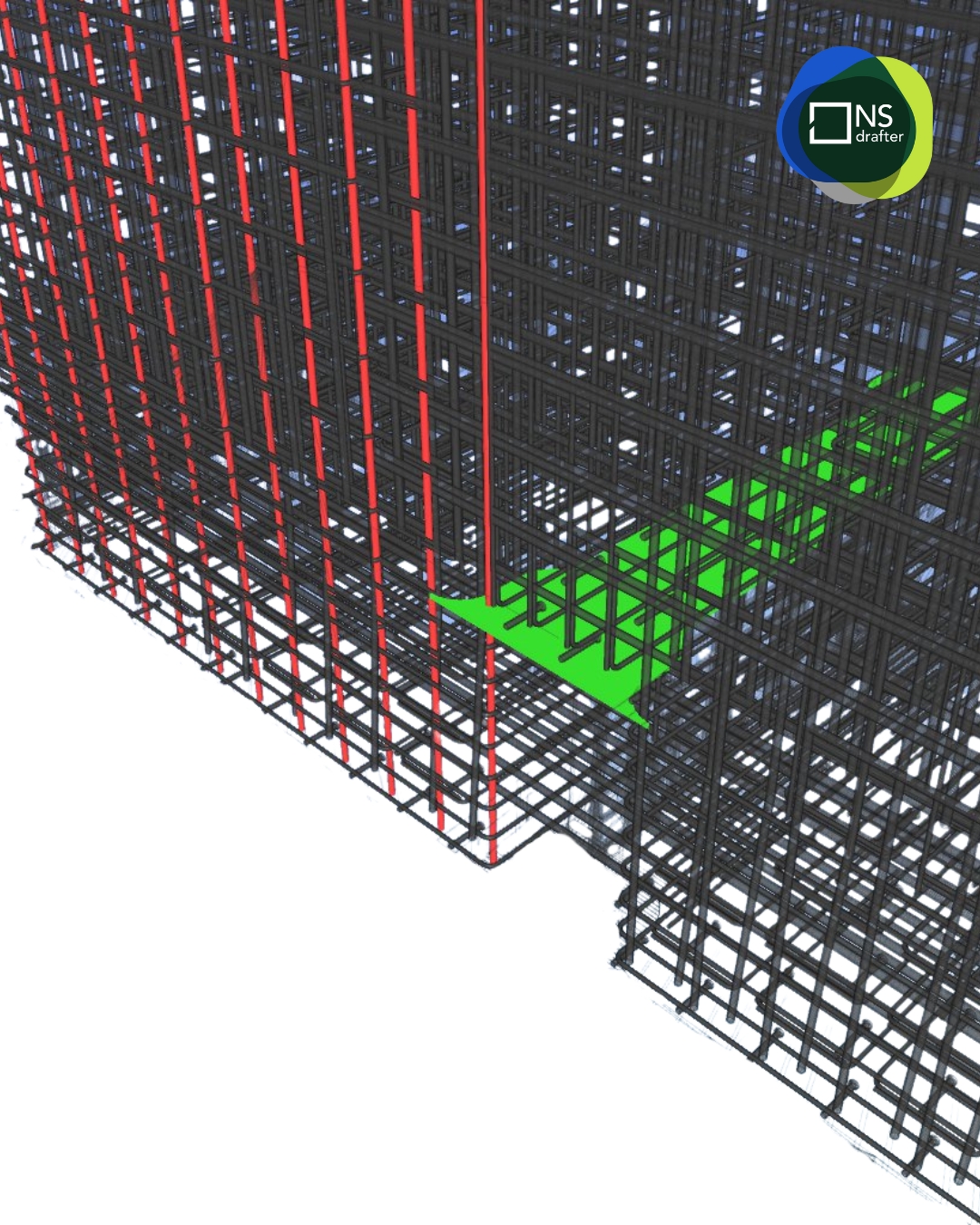

One of the most valuable functionalities of BIM is clash detection, which allows identification of conflict points between different construction systems during the design phase.

The construction industry has historically been known for its high level of risk during the execution phase. Design inconsistencies, missing details, or coordination errors between disciplines often lead to additional work on site.

Every unplanned correction means lost time, extra labor, and increased material costs, which ultimately extend project deadlines and inflate the overall budget. According to some estimates, over 30% of the total costs on large projects are directly linked to rework that could have been avoided by early identification of clashes.

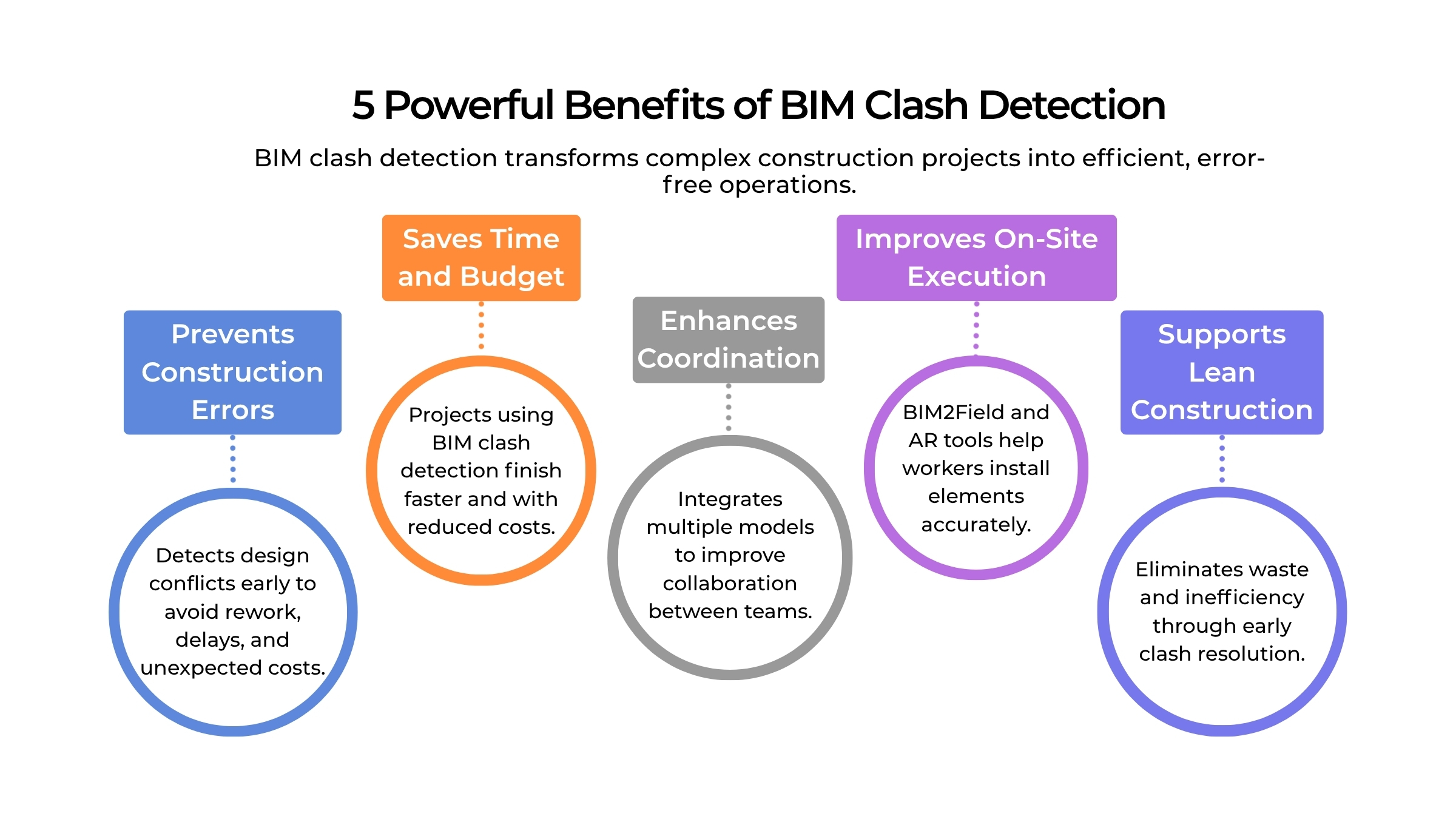

BIM clash detection enables project teams to identify and resolve conflicts before physical construction begins, reducing risks, increasing productivity, and significantly optimizing project costs.

Theoretical Framework: What Is Clash Detection?

The goal is not just to detect problems, but to resolve them in a timely manner through team and model coordination.

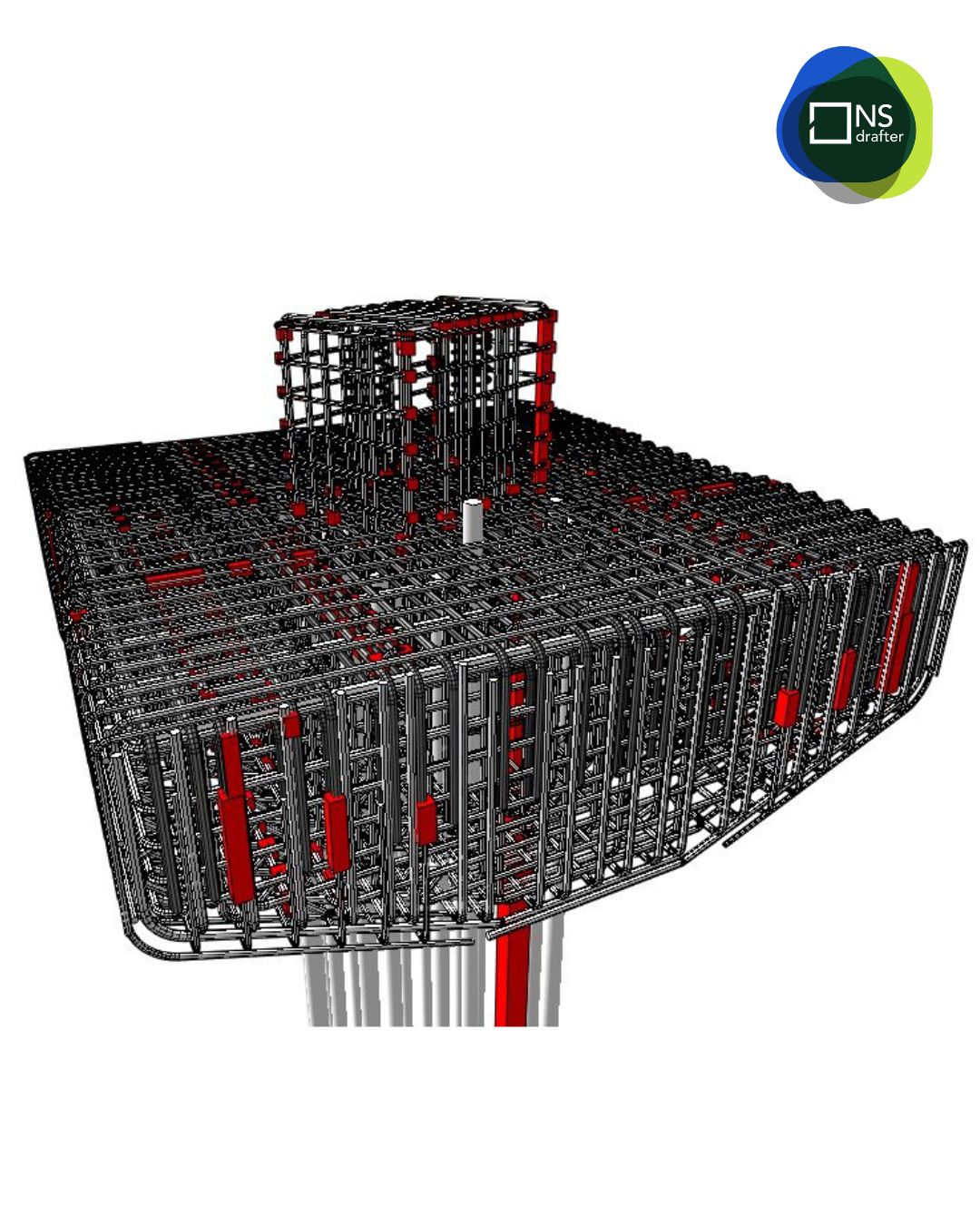

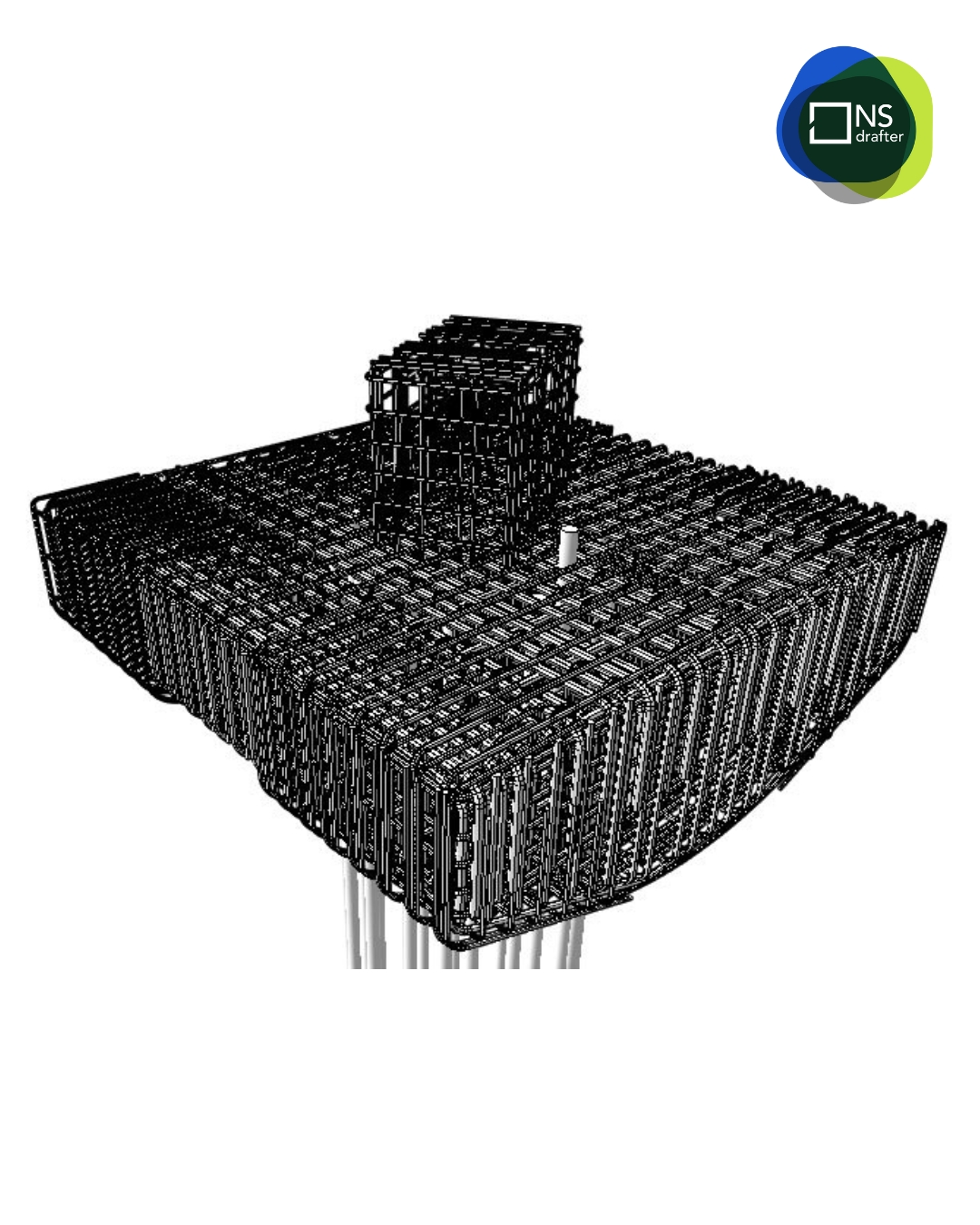

At its core, this is a software-driven process that uses geometric and semantic data from BIM models to detect errors that could cause issues during construction.

There are three main types of clashes:

- Hard Clash – occurs when physical objects (for example, a pipe and a beam) occupy the same space.

- Soft Clash – occurs when there is a violation of minimum required clearances between elements (for example, electrical wiring too close to insulated piping).

- Workflow Clash – occurs when the sequence of installation or construction phases creates issues, even though no physical clash exists.

Additionally, we can speak of informational clashes when different teams use inconsistent data or parameters in their models. Such issues often lead to misinterpretation of drawings, improper planning, and mismatched material delivery timelines.

In complex projects such as hospitals, airports, or industrial facilities, the number of disciplines and subcontractors increases the risk of clashes, making BIM clash detection a necessity rather than a luxury.

Technical Implementation and Tools

Clash detection is typically performed using software platforms such as Autodesk Navisworks, Solibri Model Checker, Trimble Connect, or Bentley Navigator. These tools allow users to import models from various disciplines, define clash detection rules, and visually identify conflicts.

The process consists of several key steps:

- Model integration loading and aligning BIM models (for example, from Revit, ArchiCAD, Tekla) into a unified workspace

- Rule definition setting clash detection parameters and tolerances (for example, minimum clearance between HVAC systems and cable trays)

- Clash detection execution the software automatically generates a list of detected clashes

- Review and categorization the team reviews the significance and priority of each conflict

- Resolution elements are redesigned or alternative solutions are proposed

- Verification the revised model is tested for the same clashes

Many teams use a clash matrix as a methodological framework for tracking and documenting all detected issues, including responsible parties and resolution deadlines. Increasingly, these reports are integrated into cloud-based platforms like Trimble Connect clash detection, allowing all project members to engage in resolving the issues collaboratively.

Quantifying the Benefits: Statistical Insights

According to studies by the National Institute of Building Sciences (NIBS), the average construction project using BIM and clash detection records the following advantages:

- 35 – 45 % fewer field changes

- 5 – 10 % reduction in overall project cost

- 7 – 12 % savings in project duration

A well-known case is the UCSF Medical Center in San Francisco, where the clash detection process identified more than 6,000 clashes before construction started, avoiding over 10 million dollars in change orders.

Another notable case is the construction of the Istanbul International Airport, where BIM clash detection was applied in every phase, resulting in up to 25% faster MEP system installation compared to traditional methods.

Practical On-Site Benefits

Clash detection is not just a tool for designers, it benefits construction teams directly. When BIM models are paired with technologies like BIM2Field and augmented or mixed reality (AR or MR), workers gain real-time insight into conflict zones.

For example, a contractor can use a tablet or AR glasses to identify the exact location of pipes, brackets, and installations, preventing incorrect placement. Time and material savings can reach up to 20% when models are coordinated in advance.

More companies are implementing automated site reports that communicate directly with the central BIM model via QR codes and AR visualization. This accelerates decision-making and reduces the need for post-facto documentation reviews.

Contractors are also increasingly using 4D and 5D BIM simulations in conjunction with clash detection results to better plan the construction sequence and budget allocations.

Clash detection even serves as a training tool. New team members can learn from previously identified mistakes, speeding up onboarding and improving execution quality.

Integration with Lean Principles

Clash detection fits naturally with the Lean Construction philosophy, which aims to eliminate all forms of waste, material, time, or energy. Early error elimination through BIM clash detection reduces rework and avoids costly on-site improvisation.

In Integrated Project Delivery (IPD) environments, clash detection becomes a key point of collaboration and quality control among all stakeholders.

Lean teams often use clash detection results as part of daily stand-up meetings, where progress and obstacles are identified and resolved proactively. This approach strengthens accountability and improves on-site workflows.

Trust among disciplines is also enhanced, as all conflicts are addressed transparently and documented.

Limitations and Challenges

Despite its advantages, BIM clash detection comes with certain limitations.

- Model quality dependency – Poorly modeled objects can lead to false positives or missed clashes.

- Lack of standardization – Different teams may have varying definitions of acceptable clashes.

- Technical limitations – Some tools struggle with large files or have complex interfaces that slow down users.

Another challenge lies in educating teams about the importance of early clash detection rather than relying on last-minute fixes on-site.

However, continuous improvement in software tools and growing adoption of standards like ISO 19650 and LOD (Level of Development) are helping to mitigate these issues.

More firms are incorporating mandatory clash detection into the BIM Execution Plan (BEP), improving consistency and accountability across disciplines.

The Future of BIM Clash Detection

As artificial intelligence and automation advance, clash detection is becoming more sophisticated. Machine learning algorithms are already used to classify clashes and suggest resolutions, while automated platforms are enabling real-time detection, directly integrated with construction site sensors and Digital Twin models.

Future BIM models will be dynamic systems that learn from mistakes and autonomously resolve potential conflicts using linked databases and IoT devices.

Clash detection will become part of a standard feedback loop between design and construction, where models update themselves based on real-world changes.

Advanced systems will even predict clashes based on real-time environmental conditions and site logistics, ensuring proactive error management.

Integrating clash data with project management systems will allow synchronization with schedules, costs, and resources, creating a fully connected decision-making ecosystem.

Conclusion

BIM clash detection is one of the most powerful components of digital construction. It prevents errors before they occur, improves communication, reduces costs, and ensures higher quality.

Successful implementation requires embedding clash detection into the core project workflow, not as a one-time control, but as an ongoing process.

As the construction industry accelerates digital transformation, BIM clash detection, coupled with tools like Trimble Connect clash detection and BIM2Field, will play an increasingly vital role in building smarter, more sustainable environments.

By using BIM to detect and resolve issues before construction begins, stakeholders can finally shift from reactive problem-solving to proactive planning, unlocking a new era of collaboration and efficiency in construction.

Frequently Asked Questions (FAQ)

Q: What is BIM Clash Detection?

A: BIM clash detection is a process used in Building Information Modeling (BIM) to identify and resolve spatial conflicts between different building systems such as structural, architectural, and MEP (mechanical, electrical, and plumbing) components before construction begins. It ensures that elements in a digital model do not physically overlap or interfere with one another, helping teams prevent costly design errors, rework, and project delays.

Q: How does the BIM clash detection procedure work?

A: The BIM clash detection procedure involves several steps including importing discipline-specific models, defining clash rules, running automated clash tests, categorizing results, resolving issues, and verifying the updated model. This procedure helps teams avoid costly mistakes on-site and ensures smoother project execution.

Q: Can BIM clash detection be done online?

A: Yes. Many cloud-based platforms offer BIM clash detection online, allowing project teams to collaborate remotely. Services like Trimble Connect or BIM 360 enable online clash checking, commenting, and model version tracking without needing desktop-installed software.

Q: What are BIM clash detection services?

A: BIM clash detection services are professional offerings by BIM consultants or companies that handle the coordination of multi-discipline models. These services typically include clash testing, reporting, and resolution strategies, and are especially valuable for firms without in-house BIM expertise.

Q: What is a BIM clash detection report?

A: A BIM clash detection report is an automatically generated document that lists all detected clashes in a project model. It includes the location, involved elements, severity, responsible discipline, and often screenshots or 3D views. This report helps teams systematically resolve issues during coordination meetings.