From 2018 Startup to +30 Countries: Our Journey to Flawless Rebar Detailing

The Journey to Flawless Rebar Detailing

Precision in rebar detailing, powered by BIM is reshaping how complex monolithic reinforced concrete structures are delivered. But behind every “error-free” drawing lies a story of persistence, teamwork, and a vision that started small.

This story takes you from our early beginnings in 2017 to a projects that left our clients both surprised and delighted, and sets a benchmark for how we deliver today.

Our Story

The story of NS Drafter doesn’t begin in a boardroom or a modern office tower. It begins in 2017, in a modest apartment where two colleagues, Ognjen and Aljoša, decided to take a leap of faith.

After leaving the company where they had worked together, they believed there was a better way to approach rebar detailing: more agile, more precise, and far more client-focused.

Armed with laptops, endless coffee, and determination, they spent their days producing reinforcement drawings and their nights answering emails.

In October of the same year, the first version of the NS Drafter website went live. Coupled with freelancing platforms, it became their window to clients across the global construction industry.

Their vision was simple yet bold: deliver rebar detailing and modeling services with a level of precision that minimizes errors and reduces the need for corrections to the greatest extent possible.

Soon after, the mission grew.

Four colleagues from their university – Nikola, Aleksandra, Milan, and Miloš, joined forces.

With six passionate professionals, the foundation of the company was laid. In June 2018, NS Drafter was officially incorporated.

From day one, the team embraced a principle that still defines us: we are a young company, and we will never treat your project as just another project. That mindset, paired with relentless development of our craft in rebar detailing, became our DNA.

Today, after working on more than 300,000 tons of reinforcement across 30+ countries, our portfolio shows how BIM workflows can transform delivery standards in construction.

From Early Steps To Complex Steel Structures – Industrial Complex, USA

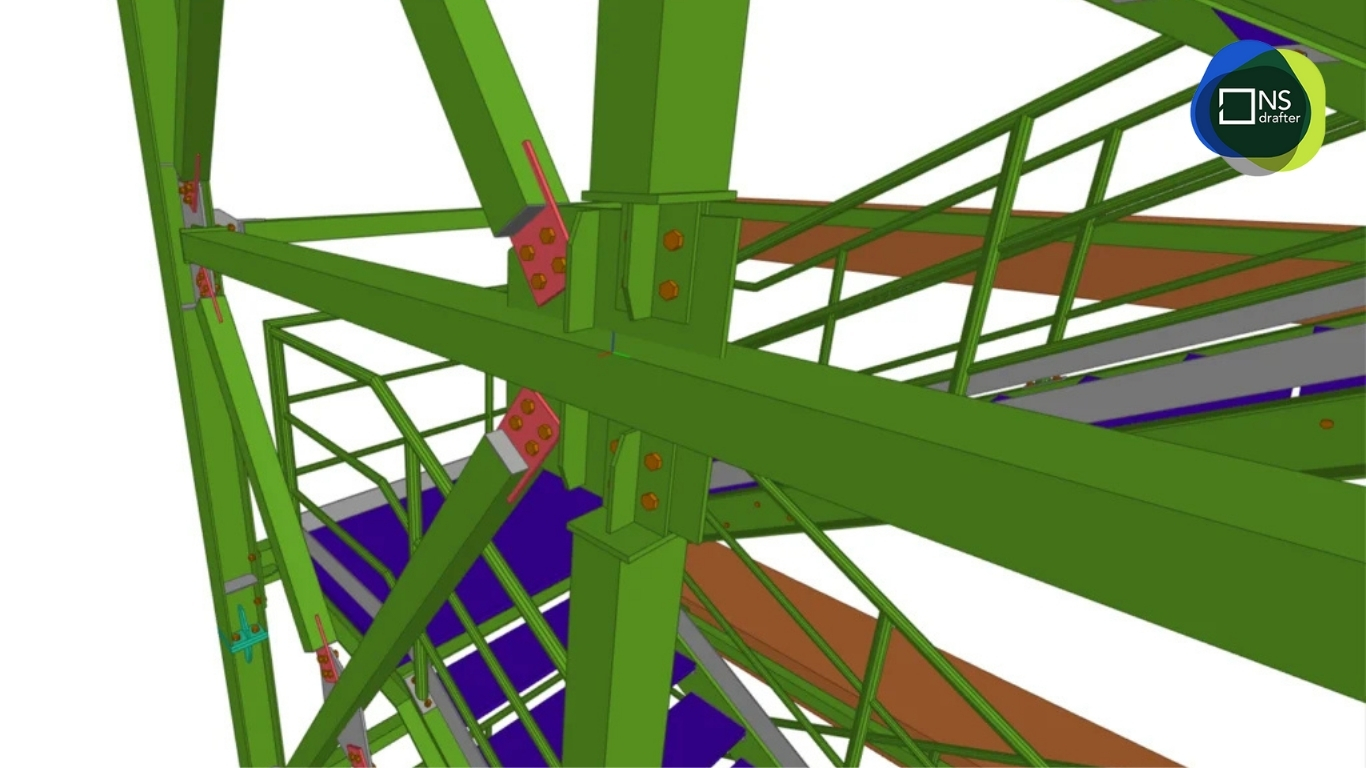

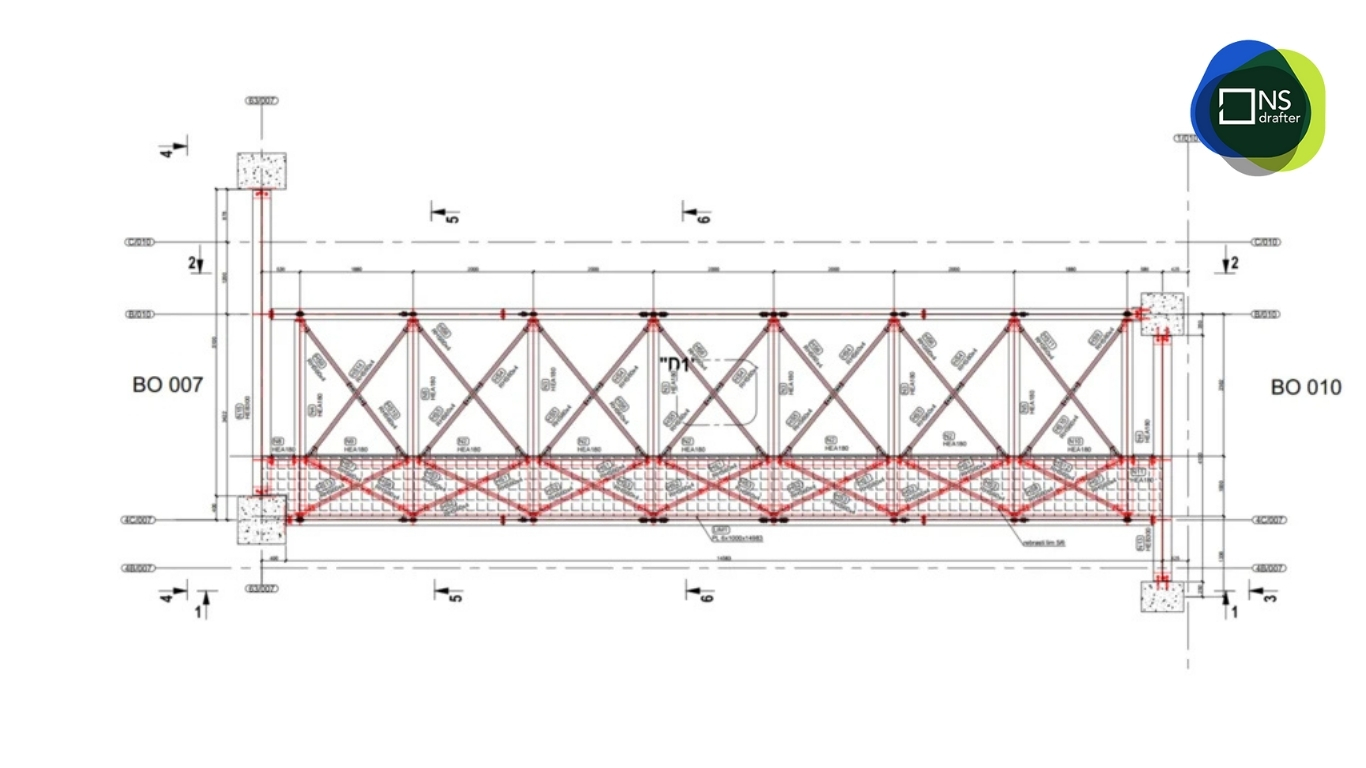

At an automotive parts manufacturing complex in the United States, we were tasked with detailing a 10-story steel stairway system that combined architectural clarity with strict functional demands.

Tight space constraints between floors meant every connection: stringers, beams, and custom railings – had to be exact.

Through early consultations with the client’s engineering and fabrication teams, we identified critical tolerances, areas of potential congestion, and other constructability challenges.

Using Tekla Model Sharing, our team collaborated in real time with engineers and fabricators, resolving clashes, disconnected elements, and design inconsistencies before drawings reached the shop floor.

The outcome: client emphasized how clear drawings and error-free rebar detailing documentation directly improved on-site efficiency, keeping construction on schedule and reducing costs.

This project proved once again that combining BIM rebar modeling, early clash detection, and emerging AI in rebar detailing tools sets a new benchmark for reliability in construction.

Consultations That Made the Difference

Before opening software or modeling a single bar, we invested in consultations with the client’s engineering team.

These sessions weren’t about ticking boxes; they were about understanding priorities.

Which structural zones posed the greatest risk of congestion? Where were the contractor’s concerns about pouring logistics? What lessons had the client learned from previous projects where detailing errors caused site delays?

These conversations helped us frame our rebar detailing approach not just as a technical task, but as a collaborative process aimed at de-risking construction.

Method That Scales: BIM + AI + QA

Every project starts with a clear understanding of client needs, from bar diameters and spacing to lap lengths, coupler policies, and cover requirements.

A preliminary BIM model allowed us to run clash detection early, spotting conflicts between reinforcement, formwork, and MEP sleeves before they could escalate into costly mistakes.

By combining BIM with AI in rebar detailing, we reduced the risk of human error and improved efficiency. Clash detection was applied throughout the process to keep layouts buildable, while AI in Tekla Structures now classify past project drawings in cloud libraries and automatically generate new fabrication drawings from the best matches. This speeds up delivery, reduces manual work, and ensures consistent quality.

Every package went through internal peer reviews before reaching the client. Instead of relying on last-minute fixes, we used structured QA checklists, ensuring consistency and quality.

Weekly updates through BIM platforms, combined with structured feedback tracking, meant no comment was overlooked. Clients stayed in the loop, and revisions, when they appeared were handled immediately.

The Result: Error-Free Submittals

At the end, we delivered a complete 3D reinforcement model, practical 2D drawings for site execution, and accurate quantity takeoffs. The client’s response said it all: “This is the first time I received something without a single correction.”

On site, rebar installation and concrete pours ran without stoppages. The contractor reported significant time and cost savings, estimating nearly 10 % reduced installation costs compared to similar projects.

Global Research Spotlight: AI in Rebar Detailing

A recent peer-reviewed study demonstrates how combining BIM data with AI-driven metaheuristics can materially cut steel use and waste in complex works.

Applied to a diaphragm wall at a Singapore MRT station, the framework (Python + Whale Optimization Algorithm, special-length bars, and strategic couplers) achieved 19.76 % less rebar, 84.57 % less cutting waste, 17.4 % lower embodied carbon, and 14.57 % total cost savings while running optimizations in under 20 seconds.

This supports our approach to AI in rebar detailing and validates the impact of data-driven workflows on constructability and sustainability.

Lessons Learned (So You Don’t Have To)

BIM and clash detection prevent rework before it reaches the site. AI in rebar detailing optimize layouts, saving time and materials. Structured QA beats improvisation, consistency builds trust. Experience compounds – since 2018 and 300,000 tons detailed, we’ve refined a process that scales.

And the industry is moving in the same direction: Tekla Structures 2025 introduced its AI Cloud Fabrication drawings feature, which uses AI to classify past project drawings and generate new fabrication drawings from the best matches.

ALLPLAN 2025 launched powerful AI-driven visualization and automated reinforcement modeling tools. These updates show that AI in rebar detailing is no longer experimental, it’s becoming an industry standard embraced by the biggest BIM platforms worldwide.

Reflections: Beyond Tools and Numbers

The tools matter – BIM platforms, clash detection, AI in rebar detailing optimizations. But what really drove this success was the combination of technology with human collaboration.

Our early consultations gave us insight into the client’s biggest concerns. Our QA processes converted experience into consistency. And our agility, responding within 24 hours, always gave the client confidence that their project was in safe hands.

The words we heard at the end – “This is the first time I received something without a single correction” weren’t just praise. They were proof that the values we set back in 2017, in a small apartment with laptops and dreams, still guide us today.

Conclusion

From long nights in 2017, when NS Drafter was just two engineers chasing a vision, to today’s large-scale projects processed with precision, the journey has been about one thing: earning client trust through flawless delivery.

With AI in rebar detailing and BIM methodology as our foundation, and with more than 300,000 tons of rebar detailed across 30+ countries, we continue to set new standards in reliability, agility, and precision.

If you want your next monolithic project to start without delays or endless revisions, reach out. Let’s build it right the first time.

FAQ

Q: What is rebar detailing and why is it important?

A: Rebar detailing is the process of creating detailed drawings and models of reinforcement for concrete structures. It ensures that reinforcement is correctly sized, positioned, and connected on site, preventing costly mistakes, delays, and unnecessary expenses.

Q: How does AI help in rebar detailing?

A: AI algorithms optimize bar layouts, reduce the risk of human error, and help detect clashes before construction. When combined with BIM models, AI enables lower steel consumption, less waste, and faster delivery of documentation.

Q: What are the main benefits of the BIM + AI approach?

A: The biggest advantages are time and material savings, higher model accuracy, reduced costs, and greater site safety. Studies show that AI optimization in rebar detailing can reduce steel usage by up to 20% and cutting waste by up to 80%.

Q: In which countries have you worked on projects?

A: Our team has detailed more than 300,000 tons of reinforcement across 30+ countries worldwide. This global experience allows us to quickly adapt to local standards and apply best practices.

Q: How can I collaborate with you on my next project?

A: Simply contact us via email [email protected]. We respond within 24 hours and provide consultations to define all requirements and deliver solutions without delays or revisions.